Top 10 Solar Project Solution Factory In China

Take silicon material as an example. Before the end of 2022, the price of silicon material has been soaring, reaching the 300 yuan/kg mark, and "silicon is king" has become popular. As silicon material production capacity continued to expand, the supply side increased its volume significantly. Eventually, silicon prices halved from their high levels and continued to fall, with a drop of more than 70% at one time.

Although silicon material prices have picked up slightly recently, this is a temporary contraction due to the long period of silicon material construction and production. In the future, as new production capacity is gradually put into production and volume is increased, silicon material prices are expected to drop to 50 yuan/kg.

As prices fall, the profit margins of photovoltaic manufacturing companies shrink. In order to recover part of the fixed costs, companies tend to stop production to reduce losses only when the price is lower than the average variable cost. Therefore, the supply curve of a photovoltaic manufacturing enterprise is the intersection of the marginal cost line and the average variable cost and above.

Under excessive competition, the market equilibrium price will drop to between the industry's average total cost and average variable cost, and the industry's average profitability will then be negative. However, the fact that the average industry profit level is negative does not mean that all companies will be in a state of loss.

For those companies with leading technology, efficient management, and dominant brands, they can control the average total cost below the market price and achieve profitability.

For those companies whose average total cost is higher than the market price, short-term losses may turn into long-term losses and eventually exit the market; if cost reduction and efficiency increase are obvious, short-term losses can also be reversed in the medium to long term and profits can be achieved in the medium to long term.

It can be seen that in an overly competitive market environment, the key to determining the survival of an enterprise is its short-term cost and long-term cost.

Figure 6: Photovoltaic enterprise supply curve

The industry involution caused by severe oversupply in the short term is very likely to become long-term, and the "winter" of industry involution will not end in one or two years.

Enterprises with backward production capacity are characterized by weak financial strength, low brand awareness, slow technological updates, poor management efficiency, and high long-term costs. It will be difficult for them to see the arrival of the industry's spring.

At a time of severe industry involution and technology iteration, photovoltaic companies are particularly struggling with whether they can bet on the correct technical route.

Technology iteration, who loses and who wins?

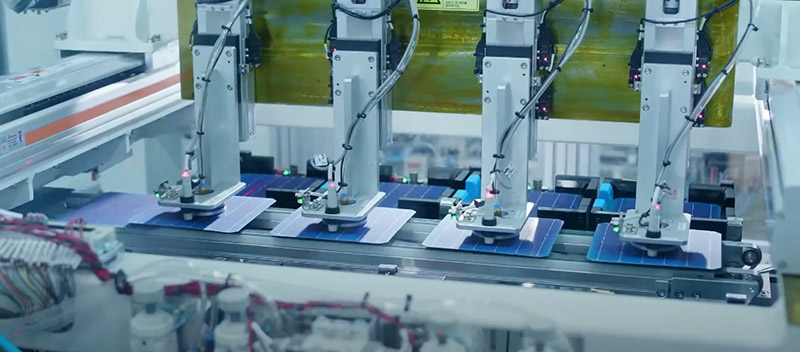

Currently, the photovoltaic industry is ushering in a new round of technological changes.

PERC technology, which has dominated the photovoltaic industry for several years, is about to give way to the new generation of power represented by N-type technology. However, the new generation of technologies is diverse and each has its own strengths and weaknesses. Which one can lead to the bright road and become the king of the future? During the window period for the development of new technologies, which companies will seize the opportunity and shake up the pattern of the photovoltaic industry?

At present, the hot development technology routes in the photovoltaic industry mainly include N-type TOPCon, HJT, BC, and perovskite.

From the perspective of comprehensive cost, technical difficulty, conversion efficiency, etc., each technical route has its own advantages and disadvantages.

In the short term, due to the relatively mature technology, TOPCon and HJT seem to have a greater chance of succeeding PERC.

Among them, the advantage of TOPCon is that the conversion efficiency is higher than HJT, the production line is compatible with PERC, and the cost performance is higher than HJT; the advantage of HJT is that there are fewer production processes, the yield rate is higher than TOPCon, and the conversion efficiency can also exceed 29% through lamination technology.

In terms of the scale of installed production capacity, photovoltaic manufacturing companies tend to bet on TOPCon, which will be more clear. If HJT can speed up and reduce costs, and realize the industrialization of lamination technology as soon as possible, there will still be opportunities to overtake TOPCon in corners in the future.

The conversion efficiency of BC and perovskite is higher than TOPCon and HJT. BC has the characteristics of a "platform". By stacking it with other battery technologies, it can achieve higher conversion efficiency. Its disadvantages are that the production process is complicated and the equipment cost is relatively high. However, it does not rule out that individual companies have mastered the core technology and can simplify process and reduce manufacturing costs.

Compared with the current mainstream crystalline silicon cells, perovskite has a simple process. Through stacking, the conversion efficiency can exceed 50%, which is revolutionary. However, due to technical limitations, perovskite has poor stability and may not be used in the short term. It cannot be industrialized on a large scale.

Currently, some companies are deploying multiple technical routes at the same time. Although risks are dispersed, it also disperses resources and increases management difficulty. Most companies choose to "give it a go" and bet on the technology route they believe is the most promising. Although they can achieve specialized development, once this route fails to meet expectations of cost reduction and efficiency improvement, they will be relatively disadvantaged in the future. , enterprises will also pay a heavy price.

At the turning point of the cycle, a storm will arise?

With the long-term overcapacity and different paths for technological upgrading, the photovoltaic industry is bound to face a storm as it moves forward, causing industry shocks.

There have been at least three major shocks in the development history of the photovoltaic industry. Each shock will severely damage the entire industry, causing a large number of photovoltaic-related companies to collapse one after another. Will there be another shock in the future? How is it different from the first three shocks? Will the industry usher in the darkest moment like the previous three times?

The first three industry shocks were tragic mainly because the photovoltaic industry was not yet mature at that time, and the global market relied on various subsidies. When the export or policy environment changes, demand suddenly shrinks, and a large amount of production capacity is difficult to digest, which will inevitably lead to the cessation of business and bankruptcy of photovoltaic companies.

Future industry shocks will be due to overheating on the supply side. Today, the photovoltaic industry is in a mature stage of development and has been able to break away from financial subsidies and achieve grid parity. At the same time, the industry is facing technological iterations. The recent layout of photovoltaic companies is mainly anchored in advanced production capacity. Even if the industry elimination competition begins, backward production capacity will be the first to be eliminated.

With the dual carbon targets as the backing, the global photovoltaic terminal market demand will remain strong in the long term. Even without policy support, the photovoltaic industry should be able to recover from the shock relatively quickly. If the reform of the power system and mechanism proceeds smoothly, photovoltaic grid-connected consumption will no longer be a bottleneck, and the blockage of the electricity price transmission mechanism will be completely cleared, which will drive the photovoltaic industry to quickly smooth out possible future shocks.

picture

Polycrystalline silicon technology has made GCL a success, and monocrystalline silicon technology has made LONGi a success. When PERC succeeded BSF, Tongwei, Aixu, Jinko and JA Solar became increasingly prominent. The future industry shock will coincide with the window period for the N-type to rise. Will the photovoltaic industry pattern be reshaped?

Can SMEs catch up? Can cross-border enterprises successfully transform? Can the status of leading companies be shaken?

The advantage of large companies lies in their "bigness", but their shortcomings are also due to their "bigness". For leading enterprises, they are stronger than small and medium-sized enterprises and cross-border enterprises in terms of capital chain, talent team and market influence, and their status seems to be difficult to shake. But it is precisely because of "bigness" that large companies need to withstand greater risks when betting on new technology routes. If the wrong technical route is taken, tens of billions of investments will be difficult to recover.

The comprehensive strength of small and medium-sized enterprises is weak and it is difficult for them to compete head-on with leading enterprises. If you bet on technical routes such as BC or HJT that are difficult to industrialize and recover investment in the short term, you will easily fall into the dilemma of shortage of funds. However, small and medium-sized enterprises have strong ability to correct deviations, have the courage to "go all-in", and can go to the extreme on a certain technical route. Currently, multiple lines are running in parallel, lamination technology is hot, and photovoltaic manufacturing companies are very entangled in the technical direction.

For cross-border enterprises, although the photovoltaic track has bright prospects, the technical threshold is high, and it is difficult for latecomers to shake the established pattern of the photovoltaic industry. However, the current time is when the old and new technology routes are alternating. On the new technology route, old and new companies are on the same starting line. Cross-border companies do not have the burden of old production capacity, so it is an opportunity to enter the industry. However, cross-border enterprises have little brand power in the photovoltaic industry, have no influence, have low market recognition, and face greater risks.

The King of the Democratic Republic of the Congo has provided a solar energy storage power station system for the village of Bunkeya to meet the electricity needs of 2500 small households in the village. As the village currently lacks access to the grid, the King requested the design of a 1MW solar panel system paired with a 1.8MWh lithium battery storage system to power the entire village.