Top 10 Solar Project Solution Factory In China

I’m writing this from my desk, finally back after a long but incredibly rewarding trip to Timor-Leste. The memory of the humid, tropical air hitting me as I stepped off the plane in Dili on September 15th is still fresh. I’d flown in from Guangzhou the day before, my bags packed not with souvenirs, but with technical manuals, diagnostic tools, and a keen sense of purpose. Our mission: to ensure the successful commissioning and knowledge transfer for a 100kW hybrid solar system powering a critical telecom base in a remote area.

This project was more than just an installation; it was about ensuring a community stays connected. The moment I landed, I went straight to work, meeting with the client to understand the site's specific challenges and the progress their local team had made.

The real work began at the project site. Under the intense sun, we rolled up our sleeves. My first task was a meticulous inspection. I went over every solar string, cross-referencing each panel with the design schematics. A single misstep here could impact the entire system's efficiency. With a voltage tester in hand, I checked each string, noting any irregularities for the team to address. It’s precise, sometimes tedious work, but absolutely vital.

Next came the safety systems. I spent a good amount of time with the local technicians on the lightning protection and grounding. I showed them how to properly use a ground resistance tester, explaining why a well-grounded system isn’t just a line on a drawing—it’s what keeps everything safe during a storm. Seeing them confidently take measurements themselves was a small but significant victory.

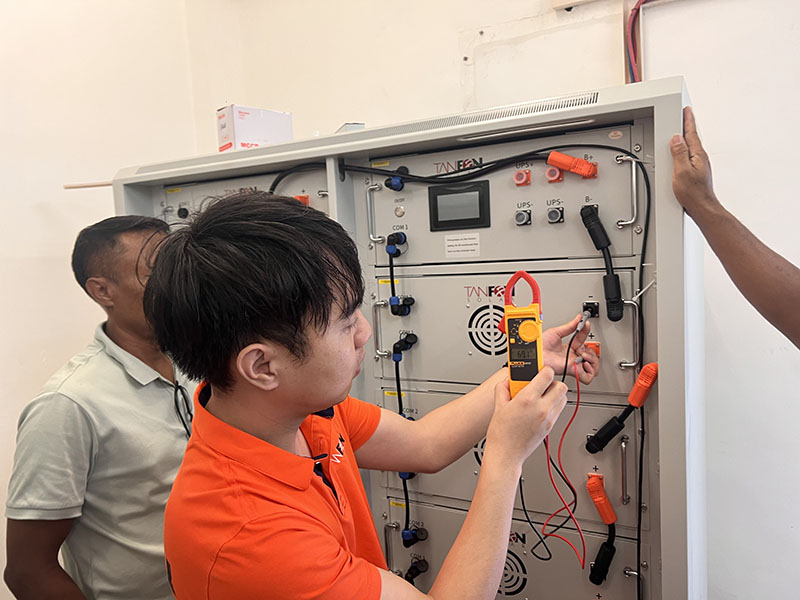

Then we moved to the heart of the system: the batteries and the MPS inverter. Connecting the battery clusters correctly is crucial. I walked them through the entire process, from stripping wires to checking the voltage of each individual cell. When we fired up the inverter, we inevitably hit a few alarm codes—you always do. But instead of just fixing them, we used it as a training opportunity. We troubleshooted an overvoltage warning together, and I explained how to diagnose similar issues in the future. The goal was to leave them empowered, not dependent.

Perhaps the most satisfying part was guiding the client through the remote monitoring app and the EMS backend. Seeing their faces light up as they registered an account and saw real-time data from the system on their phones was fantastic. They’re now able to monitor performance from anywhere, which gives them immense peace of mind. We concluded with comprehensive training sessions, covering everything from basic principles to daily maintenance. Their questions were sharp and engaged, which told me they were truly grasping the material.

Now, the system is live. It’s a robust hybrid setup that intelligently uses solar power, stores excess energy in batteries, and only calls on the diesel generator as a last resort. It’s expected to cut fuel costs by up to 70% and reduce carbon emissions significantly. But beyond the numbers, it’s about providing reliable communication for a remote area, which is a powerful thing to be a part of.

This project is a testament to what we do at TANFON: we don’t just deliver equipment; we deliver solutions and, more importantly, we transfer the knowledge to keep them running for years to come. It was a challenging trip, but the success of the project and the gratitude of the client made every bit of effort worthwhile.

The King of the Democratic Republic of the Congo has provided a solar energy storage power station system for the village of Bunkeya to meet the electricity needs of 2500 small households in the village. As the village currently lacks access to the grid, the King requested the design of a 1MW solar panel system paired with a 1.8MWh lithium battery storage system to power the entire village.